The magnetic reeds enclosed in our liquid level sensors are extremely reliable and long-lasting when utilized properly. Failures are nearly always a result of current overloading. Pumps, solenoids and many other devices that require control by a liquid level sensor carry "steady state" current ratings. These devices can draw ten times (or more) their steady state power ratings on start-up or shut-down. When the reeds inside our switches are exposed to this kind of "spiking voltage" they can overheat and become deformed. In some cases they may even weld together or break off, causing the switch circuit to remain closed (or open) regardless of the level of the float. Deformed reeds can also function intermittently, causing problems with troubleshooting. A 50 watt float switch can be destroyed by a pump rated at 6 watts and, unfortunately, it may take many cycles before the failure occurs.

Because they can destroy an otherwise very reliable float switch, care must be taken to completely isolate the switch from the current drawn by pumps, solenoids or other devices subject to spiking voltage. Resistors or diodes may be used, but the most common solution is to utilize a circuit board or a relay.

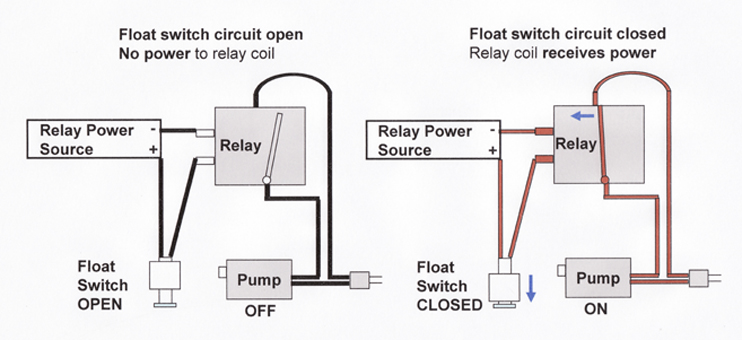

In the illustration below, a relay acts as a switch for a pump, thereby isolating the float switch from any spikes that the pump may draw. The float switch turns the relay coil on and off. In this way, the only current handled by the float switch is that small amount required by the relay coil. Please consult with your relay supplier to assure that the relay current requirements are well within the specs of the float switch.

For technical or design questions, please do not hesitate to use our Contact Form, email us at info@chicagosensor.com or call us on 773-252-9660.